Have a question?

Fuel Injection Systems Services

At Baileys Diesel Group (BDG), diesel combustion efficiency and technology are our bread and butter. We specialise in remanufacturing fuel injection systems to optimise engine performance. Drawing on over 50 years of expertise, we combine cutting-edge technology with strict calibration standards to deliver OEM-compliant solutions to our clients across Australia.

Our Fuel Injection Systems Services Include:

- Remanufacturing of Common Rail Direct Injection Systems (CRD): We precisely restore CRD systems, improving fuel delivery and enhancing combustion efficiency.

- Remanufacturing of Mechanical and Electronically Controlled Fuel Injection Pumps: Our process brings these pumps back to life with OEM standards, delivering reliable and consistent performance.

- Remanufacturing of Electronically Controlled Unit Pumps and Injectors (EUP & EUI): We rebuild EUP and EUI systems with precision, which optimises fuel flow and boosts engine output.

- Remanufacturing of Hydraulic Electronic Unit Injectors (HEUI): Our HEUI remanufacturing provides consistent power with reduced emissions and dependable performance.

- Extended Economic Life Projection: Our services extend the lifespan of fuel injection systems, which helps reduce downtime and replacement costs.

- Power & Efficiency Improvements: Remanufactured systems deliver greater power with improved fuel efficiency for optimal engine performance.

We do more than just recondition injectors — we help our clients achieve peak engine performance, reduce costs, and contribute to a greener future.

ISO Calibration, Testing, and Certification

How Baileys Diesel Group Delivers Precision & Reliability

BDG upholds the highest standards in calibration, testing, and certification. We carry out each calibration with certified fluids that meet stringent viscosity and temperature requirements. This process helps to ensure exceptional precision and reliability.

Calibration

Our calibration achieves 99.9% accuracy, guaranteeing optimal torque and consistent power through millions of combustion cycles. This accuracy enhances engine performance and extends component lifespan.

Testing

Testing is conducted to exact Engine and Fuel Pump OEM standards. We utilise state-of-the-art, OEM-recommended test benches, including:

- Hartridge

- Bosch

Certification

Certification forms the foundation of both OEM factory-supported and BDG-extended warranties. All BDG products meet or exceed OEM specifications. This commitment provides customers with trusted performance, durability, and quality assurance.

Fuel Efficiency with a Purpose

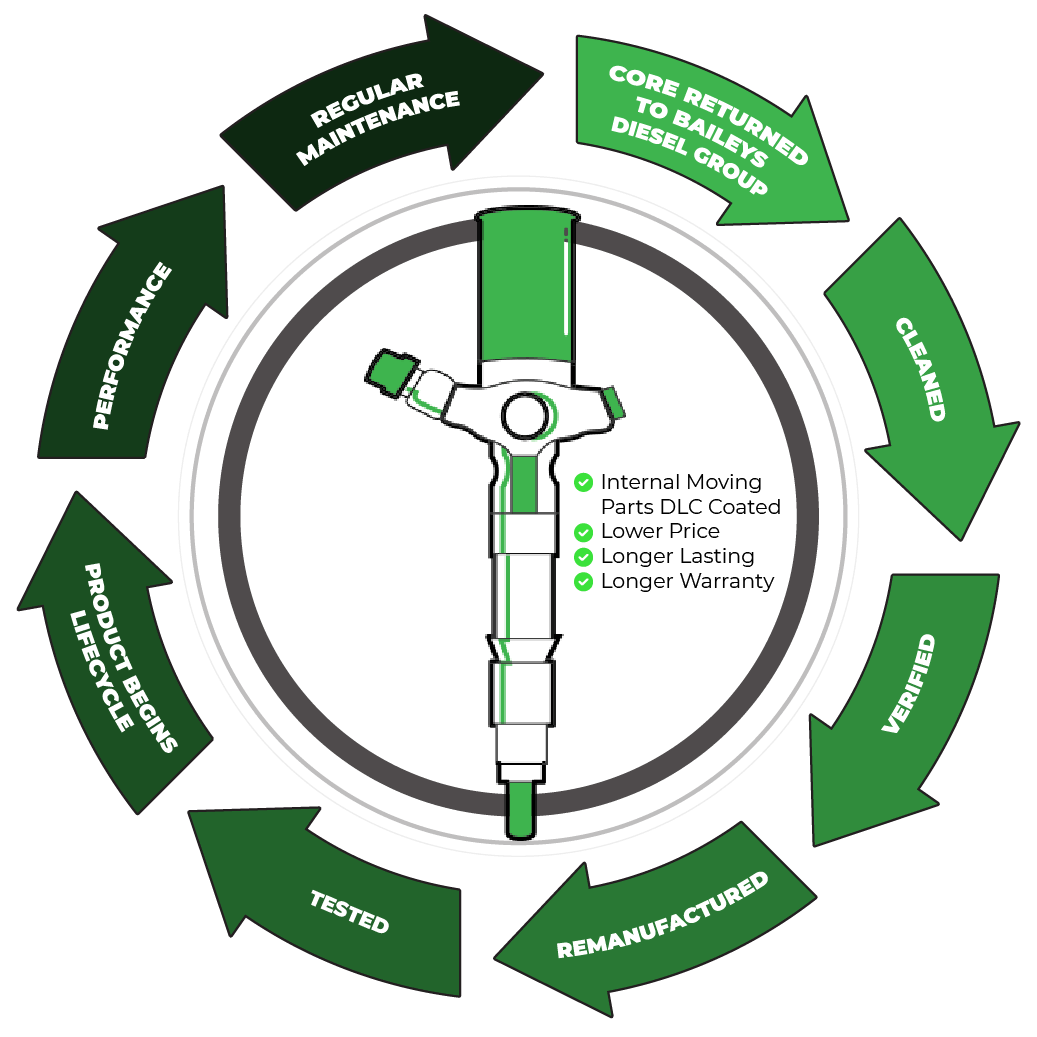

Reduce Emissions & Waste with BDG’s Remanufacturing Process

BDG takes pride in its role in reducing emissions and waste. Our diesel injector recycling and remanufacturing processes minimise environmental impact while contributing to fuel efficiency and carbon footprint reduction.

The BDG Advantage

See What Makes Baileys Diesel Group Different

Proven Expertise

With over 50 years of expertise in diesel combustion efficiency and technology, we provide trusted solutions built on a legacy of excellence.

Cost-Effective Solutions

With over 50 years of expertise in diesel combustion efficiency and technology, we provide trusted solutions built on a legacy of excellence.

OEM-Standard Quality

Every product is tested and calibrated to meet or exceed strict OEM standards to ensure durability and reliability.

Expert Trained Technicians

Our technicians are extensively trained in the latest technologies and highly experienced, allowing them to deliver reliable results every time.

Technical Support Services

We provide free tech support and resources from our qualified mechanics to assist with all your technical needs.

Hear from Our Satisfied Customers

Fuel Injection System FAQs

Are remanufactured parts as reliable as new ones?

Yes, absolutely. Remanufactured parts are held to the same, if not higher, standards than new components here at Baileys Diesel Group. Our rigorous calibration and testing processes ensure 99.9% accuracy, optimal torque, and power performance. Every product meets or exceeds OEM specifications and is backed by our extended warranties to give you complete confidence in their quality and reliability.

What types of fuel injection systems do you remanufacture?

We specialise in a wide range of fuel injection systems, including:

- Common Rail Direct Injection Systems (CRD)

- Mechanical and electronically controlled fuel injection pumps

- Electronically Controlled Unit Pumps and Injectors (EUP & EUI)

- Hydraulic Electronic Unit Injectors (HEUI)

How do you ensure accuracy in calibration?

Our calibration process uses certified fluids that meet strict viscosity and temperature standards. This precision results in 99.9% accuracy, guaranteeing superior engine performance and component durability across millions of combustion cycles.

What testing equipment do you use?

We test all systems using OEM-recommended test benches, including industry-leading brands like Hartridge and Bosch. These tools help us meet strict Engine and Fuel Pump OEM standards.

Does BDG provide warranties on remanufactured parts?

Yes. All BDG products are supported by OEM factory-backed warranties and our own extended warranties. These guarantee high performance, durability, and peace of mind.

How does BDG contribute to reducing environmental impact?

Our remanufacturing process reduces waste by extending the lifespan of fuel injection systems. We also focus on improving fuel efficiency and lowering emissions, aligning with the United Nations 2030 Agenda for reducing greenhouse gases.

What benefits can I expect from BDG’s remanufactured systems?

Our remanufactured systems improve fuel efficiency, reduce maintenance costs, and enhance engine power. They also come with extended economic life, minimising downtime and replacement expenses.

Where is BDG located?

We operate from a state-of-the-art, 1500m² facility in Wollongong, New South Wales. This centre is equipped with advanced technology to deliver world-class remanufacturing and testing services.

Can BDG assist with maintaining and improving my diesel engine?

Yes, we don’t just provide technical solutions. Our team offers guidance on maintaining your engine, improving its performance, and prolonging its lifespan.

What sets BDG apart from competitors?

With over 50 years of expertise, patented innovations, and a very strong commitment to OEM standards, BDG sets the standard for precision, performance, and reliability. Our rigorous processes, advanced testing equipment, and customer-first approach ensure you receive the best in the industry.

Are You Ready to Give Your Engine the BDG Advantage?

Contact our team today to learn more about our fuel injection systems services and how we can support your performance goals.