Have a question?

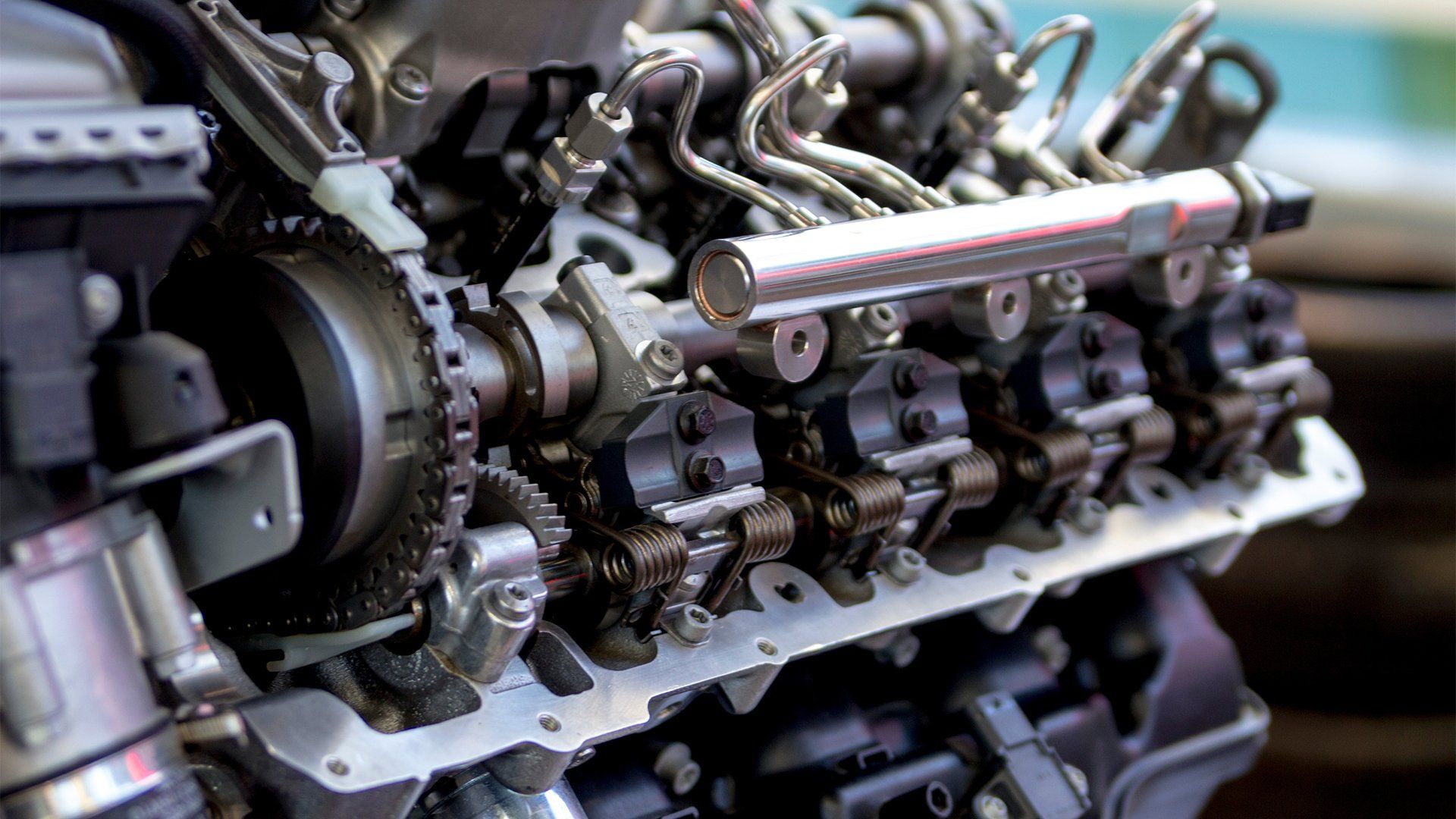

Contamination of Common Rail Diesels

If you own a common rail diesel, it's important to be aware of the risk of fuel contamination. Fuel contamination can cause a number of problems, ranging from engine damage to fuel systems failure. In some cases, it can even lead to fires.

Here at Baileys Diesel Group, we see too many fuel contamination cases and repeated failure of replaced components due to incorrect repair of the injection system. To avoid fuel contamination, it's important to use only high-quality, clean diesel fuel. If you're unsure about the quality of the fuel you're using, have it tested by a professional. If you contaminated fuel, take action immediately to clean your system and prevent further damage.

Here at Baileys Diesel Group we see too many cases of fuel contamination and repeated failure of replaced components due to incorrect repair of the injection system. Contamination can be caused by a wide range of things including but not limited to; water, particulates and petrol or other non-diesel liquids. We would like to cover a few things in regard to the prevention and correct repair of contaminated common rail diesel fuel injection systems…

What is fuel contamination?

Fuel contamination occurs when diesel fuel enters an oil system, such as the fuel lines or injection pump. The dirty fuel enters the diesel engine with fuel contamination and creates a build-up of sludge, gum, and varnish in the fuel system.

The build-up restricts fuel flow, causing the engine to limit the amount of fuel it will accept. Eventually, the parts of the engine that require the cleanest, most consistent flow of fuel wear out or fail.

As they fail, they create a new pathway for the rest of the fuel systems to become contaminated. This can create a huge and expensive headache for a trucking company.

How Fuel Contamination Occur

One of the main reasons fuel contamination occurs is because of improper maintenance. For example, it’s important to drain the fuel tank before replacing a fuel system component. If the truck is being maintained while the fuel storage tank is still full, fuel can get trapped in areas that shouldn’t be and become contaminated. Dirty hands and tools can also transfer debris from one fuel component to another, creating a pathway for contamination.

Another way contaminated fuel can occur is from an external source. If someone is siphoning diesel from a truck, the dangerous, unsecured fuel source can transfer contaminants all over the truck. Once contaminated, the truck can transfer it to other trucks on the property or to other locations.

Most Common Causes of Fuel Contamination

Diesel fuel contamination can be caused by a wide range of things including but not limited to; water, particulates and petrol or other non-diesel liquids. We would like to cover a few things in regard to the prevention and correct repair of contaminated common rail diesel fuel injection systems.

Water

Water in diesel fuel can come from the service station, moisture created in the tank from the cooling of fuel or even sucked in when submersing the tank in water i.e. a river crossing.

Water going through your fuel injection system creates many fuel problems. From lack of lubrication compared to that of diesel to the ability to almost instantly rust components of the fuel systems due to the temperature of the fuel and components. This rust then creates contamination particles causing fuel stability, however we are already past the fuel filters and this only ends up at the injectors.

While the injectors will usually be the failing component, the damage has also been done to the rest of the system i.e. rust in the fuel rail, fuel pump and fuel lines. In some cases, even the fuel tank/s will need replacement as many metal tanks will rust if water has sat in them. This means a thorough inspection of fuel tanks is essential to eliminate all rust from the system. If all components are not replaced this rust will dislodge and end up passing into the brand new set of injectors or stop the pump from working eventually.

In many cases, water contamination does not set off the factory water alarm whether this is because it has been emulsified or the filter has not displaced a large enough amount to bring on the warning lamp. In this case, the vehicle will usually run as usual however rapidly wearing components. Once stopped these vehicles can often present a non-start condition or hard to start condition. Once running, lack of power and rough idle are indications contaminated fuel may be the issue.

While modern diesel vehicles are equipped with OEM water traps and sensors in their fuel filters, often this is not enough or they do not alert the operator quick enough.

This is where extra preventative measures should be taken.

- Look for reputable service stations with high turnover as there is less chance of large amounts of water being in the fuel. Always keep your fuel receipts!

- If you have access to “cheap” diesel through the workplace or farm tanks, avoid this in your common rail vehicles it will NOT save you money in the long run.

- Ensure tank breathers are not blocked and if possible extended above where you may get water to save the fuel storage tank from pulling in a large amount of water in a water crossing event.

- Fit a secondary filter, we recommend a 2-micron secondary filter that also includes its own water trap. This gives you some water trap capabilities after the main filter and warning indicator, that way if water is coming through your main filter but it hasn’t yet set off the indicator you should catch what water makes it past until the indicator is set off.

- Installing a pre-filter will separate water yes, however when the water indicator is triggered you now have water in both your pre and main filters with the main filter now reaching its water trapping capabilities meaning the indicator is the last line of defence leaving you clueless to water in your system until a lot of the time it’s too late.

- If you do happen to have your water indicator go off in your vehicle, stop driving immediately and drain your filter. We would also recommend reporting fuel quality issues and having your fuel tanks drained and cleaned as soon as possible whilst getting your fuel systems checked for any signs that the water made it past the filter.

Pure microbial contamination is not the same as water contamination. When you have more Fatty Acid Methyl Ester (FAME) and less sulfur, it speeds up the process. As more water is added, bugs have a lot more room to grow at the point where the fuel meets the water.

Microbial growth can cause blockages, just like with water however these are usually more difficult to diagnose as you may not have a water in fuel indicator. Engine running rough, low power and black smoke are all indications of microbial contamination.

Above (L-R): Separated water, emulsified water

Particulates

Particulates can end up in the fuel systems in many ways including, poor cleanliness during maintenance, dirt ingress when refueling through the tank filler, dust through tank breather and diesel bug (usually grows when water is present).

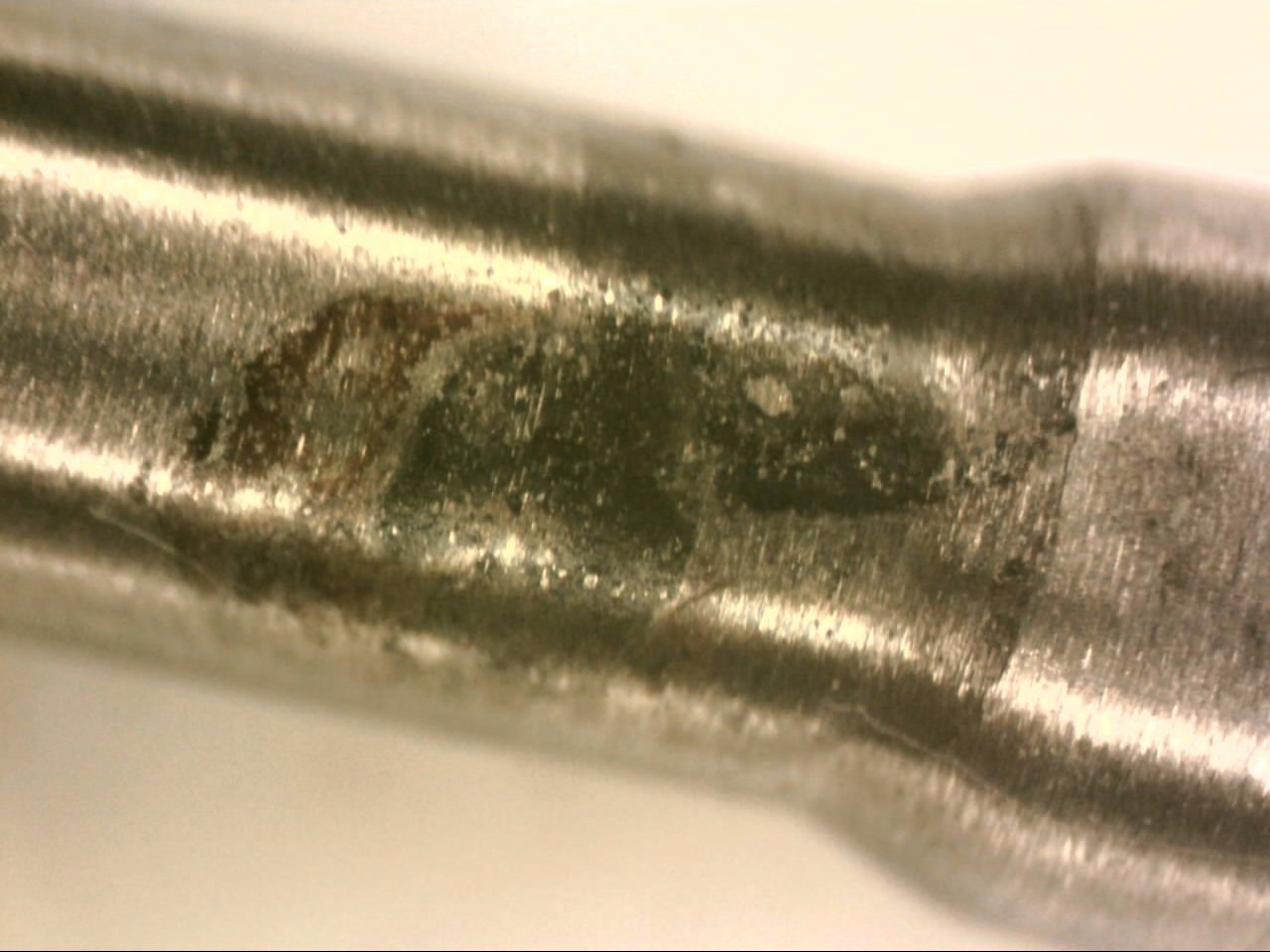

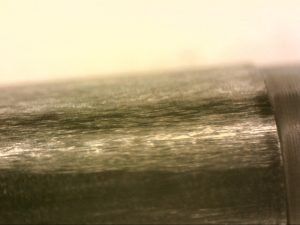

These particulates do not have to be large, it’s the smallest particulates that will cause the damage. With most factory filters ranging between 5-10 microns and injector clearances down to 2 microns. Anything between 2 and 5 microns will cause premature wear in your common rail injectors.

For example on how small this is the average human hair is around 60-80 microns in diameter, so these particles damaging your fuel systems are virtually invisible. This is the biggest reason we recommend installing a 2 micron secondary fuel filter on your common rail vehicle. Many people will say a 2 micron filter will cause restriction however our fuel manager 2 micron filter flows at 300LPH the exact same flow rate as a 30 micron fuel manager filter.

If your 2 micron filter becomes blocked after catching all the particles your factory filter has allowed through causing a fuel restriction this is better than those particles going through your injectors considering a replacement fuel filter will set you back $40 and can be kept in the vehicle rather than thousands for injectors.

To keep chances of particulate contamination to a minimum, take extra caution when replacing fuel filter or working on any part of the fuel system. Try to keep the engine bay and areas around fuel filler and tanks as clean as possible.

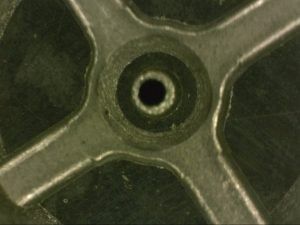

Above (L-R): Undamaged valve plate under microscope, valve plate erosion due to contamination under microscope, spindle damage due to contamination under microscope

Petrol or Other Non-diesel Fuels or Liquids

Filling a diesel vehicle with petrol happens more regularly than you would think. However there are usually two outcomes. One being you realise before starting the car or you drive the car until an issue arises.

If you do happen to fill your diesel with petrol and do not start the vehicle, get the vehicle towed to our workshop or your nearest mechanic. If the vehicle is not started the tank can be drained and re-filled with diesel with no issues. Some tanks may need to be removed to achieve proper draining of petrol.

If the vehicle is started and driven, once the petrol reaches the injection system the damage is almost instant. Although it may take a while for the car to “sound bad” or not “run well” the damage starts occurring straight away. Unlike diesel, petrol has dramatically less lubrication properties and the diesel fuel injection system relies on the diesel to lubricate all the components.

This causes all components to become much hotter than usual and running with no lubrication and a greater amount of heat, rapidly increased wear occurs. Once petrol has run through the diesel injection system no matter the amount, all components should be replaced, thus preventing premature failure.

If only failed components are changed i.e. injectors, the premature failure of other components not replaced can then produce contaminate particulates which will then be passed through the new injectors likely causing them to fail again much sooner than expected.

- Injectors

- Fuel Lines

- Fuel Rail

- Pump to Rail Fuel Line

- Fuel Pump

- In-tank pickup assembly (cleaned or replaced)

- In-tank pump if applicable (if damaged or no longer operating)

- Fuel tank cleaned and replaced if necessary (if any sign of rust)

Checking for Contamination

There are two easy to see tell tales of contamination when replacing injectors. The first would be the fuel filter. If your fuel filter is completely black or “sludgy” and “slimy” there is a good chance your vehicle has suffered a contamination related failure.

The second is the inlet filter in the injector itself. Here are pictures of contaminated and non contaminated.

Above (L-R): New, rust particles, severely contaminated

Insurance

Many of the vehicles we do this work on are covered through their comprehensive insurance policy. We highly recommend knowing whether your vehicle is covered for contamination and confirming with your insurance company what their coverage is.

Often claims require receipts of recent diesel purchases so this is a big reason to hold on to your fuel receipts. The insurance company should be notified asap when contaminated fuel is found and can aid in what they require for the claim to be processed. Never continue with the repair until confirmed by insurance.

Final Words

We hope you never have to experience this type of problem, but unfortunately it is something that does happen from time to time. If you do, please give us a call at 1800 465 328 and we will endeavour to get your vehicle back on the road asap.

Baileys Diesel Group is your one stop shop for all things diesel. From common rail injectors to DPF regeneration, our team of experts can help you with any problem you may have.